Did you know that neglected pump maintenance can lead to unexpected breakdowns, causing costly delays and significant repair expenses? Pumps are essential components in many industries, tirelessly working behind the scenes to keep operations running smoothly.

Despite their critical role, they often don’t get the attention they deserve until a problem arises. You can avoid these disruptions by implementing regular pump maintenance services, enhancing your equipment’s efficiency, and extending its lifespan.

In this blog, we’ll explore the numerous benefits of routine pump maintenance, from reducing operational costs to preventing downtime.

Why Is Pump Maintenance Important?

Preventing Downtime

It can be incredibly costly if your production line is grinding to a halt because of a pump failure. Regular maintenance helps identify potential issues before they escalate, preventing unexpected downtime.

Enhancing Efficiency

A well-maintained pump operates more efficiently. When pumps run smoothly, they consume less energy, reducing operational costs. Efficient pumps also ensure your system performs at its best, maintaining consistent output and quality.

Prolonging Equipment Life

Regular maintenance can help your pumps last longer. By addressing wear and tear early, you can avoid major repairs or replacements, ultimately extending the life of your equipment.

Key Components Of Pump Maintenance

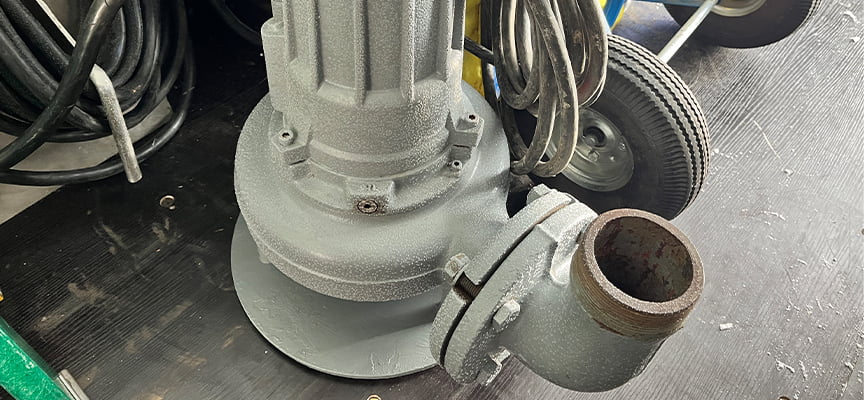

Inspection And Cleaning

The first step in maintenance is inspecting your pumps regularly. Look for signs of wear, corrosion, or leaks. Cleaning is equally important, as debris and buildup can hinder performance.

Lubrication

Lubrication reduces friction between moving parts, preventing wear and overheating. Make sure to use the correct type of lubricant recommended by the manufacturer. Regular lubrication keeps your pump running smoothly and quietly.

Alignment And Balancing

Misaligned or unbalanced pumps can cause vibrations, leading to excessive wear and tear. Regularly checking and adjusting the alignment and balance ensures that your pump operates steadily, reducing the risk of damage.

Seal And Bearing Checks

Seals and bearings are critical components of any pump. Regularly inspect and replace worn-out seals and bearings to prevent leaks and ensure smooth operation. Neglecting these small parts can lead to significant issues over time.

Benefits Of Professional Pump Maintenance Services

Expertise And Experience

Professional pump maintenance services bring expertise and experience to the table. They know what to look for and how to address issues efficiently. Why risk doing it yourself when experts can handle it for you?

Advanced Tools And Techniques

Professional services use advanced tools and techniques for maintenance. They can perform tasks like vibration analysis and thermographic inspections that are beyond the scope of regular maintenance.

These advanced methods can detect problems early, preventing costly repairs.

Comprehensive Service Plans

A professional pump maintenance service offers comprehensive plans tailored to your specific needs. Whether it’s a routine check-up or an emergency repair, they have you covered.

This tailored approach ensures that your pumps receive the best care possible.

Safety And Compliance

Ensuring the safety and compliance of your equipment is paramount. Professional pump maintenance services help you comply with industry regulations and safety standards.

Regular inspections and maintenance reduce the risk of accidents and equipment failures, ensuring a safer working environment. Compliance with safety regulations not only protects your employees but also shields your business from potential legal issues and fines.

Also Read: CRMT Contracting: Your Trusted Partner In Water Management And Environmental Services

How Often Should You Perform Pump Maintenance?

Manufacturer’s Recommendations

Always start with the manufacturer’s recommendations. They provide guidelines based on the pump’s design and usage. Following these guidelines ensures that you maintain your pump correctly.

Usage And Environment

Consider how often and in what conditions your pumps operate. Pumps used in harsh environments or for continuous operations may require more frequent maintenance. Adjust your maintenance schedule accordingly to keep your pumps in top condition.

Regular Inspections

Incorporate regular inspections into your routine. Monthly or quarterly inspections can help catch minor issues before they become major problems. Regular checks keep you informed about the health of your pumps.

About Us

CRMT Contracting provides water management solutions, equipment rentals, and environmental consulting. With our expert team and advanced technologies, we ensure that your water is safe, clean, and of the highest quality.

Contact us today to learn more about our professional water treatment services and how we can help you achieve optimal water quality.